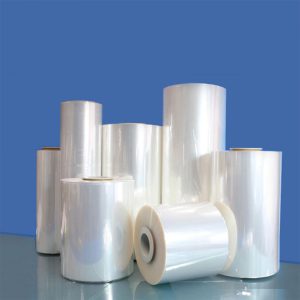

White and Colored Polyethylene Film

What is polyethylene film? Polyethylene film, known by many names such as sheet, plastic, plastic film, and poly film in the market, is obtained from oil and is the first best-selling plastic in the world. In industries, this product is sold and supplied in rolls so that it can be quickly shipped and used. In addition to the product’s specific features, it is possible to add different materials to its structure and produce unique and customized products. This film is a protective plastic placed as an external layer on various products in industries and prevents any damage to them. Plastic packaging of food and health products is produced from polyethylene film. Everywhere you look, you will see a product made from polyethylene film. The white and colored polyethylene film of Pooshan Plastic Company is the first choice of large Iranian companies due to its excellent features and impressive quality.

During the production process of this product, various colors, such as red, blue, green, white, yellow, etc., are added to its structure, so it is a better choice for producing plastic packaging. Colored polyethylene is printable and attractive designs; colors can be worked on it.

The Polyethylene Film Structure of Pooshan Plastic Company

Pooshan Plastic Company produces all kinds of packaging films with polyethylene raw material, linear type with light density (LLDPE). This linear light polymer is the best and most flexible type of plastic. Flexibility, resistance and impressive tensile strength, compared to other plastics from similar brands on the market, are just a few of the advantages of this film. To increase the strength and improve the structure, the film is supplied in three layers, and as a result, it does not get torn or punctured easily.

Advantages of Using Polyethylene Film

Polyethylene film is more than typical and simple packaging and has countless advantages. These advantages have made this film the first choice of industries to cover various products. In the following, we will examine its key features.

- Complete protection: This film’s first and most important duty is to protect the items inside. Polyethylene is leakproof and great for heat sealing. As a result, it can be wrapped and sealed around products and have a completely waterproof package. This feature has made this material popular in the electronics industry because it prevents parts from being tampered with and guarantees their safety.

- Lightweight: One of the constant concerns of the shipping and packaging industry is weight. The lighter the weight of the cover package, the easier the shipping process will be. Polyethylene film is a thin layer that is extremely light in weight. The film adheres perfectly to the products, so it takes up no extra space, and no storage space is required. Easy transportation also reduces carbon production.

- Excellent flexibility: polyethylene film is produced from soft and flexible LLDPE raw material. The plastic produced from this material is puncture-resistant and has excellent tensile strength and molds to the shape of the items placed inside.

- Compatibility: Polyethylene is highly compatible; in its production, various materials can be added to it and give it distinctive features. White, transparent and colored polyethylene are also quickly produced so they can be used for different products and needs. PE roll films are marketed in different widths and thicknesses.

- Cheap price: the process of production and processing of polyethylene is relatively easy, and its raw material is available; for this reason, it is one of the inexpensive materials that has found its way into the production of various products.

- Hygienic: One of the problems of using PVC film is the toxic gases it emits during use, which causes damage to the employees in addition to the environment. Polyethylene film does not have these problems and can be recycled.

The Use of Polyethylene Nylon of Pooshan Plastic Company

Polyethylene is the best-selling plastic film with excellent quality and hygienic structure. All kinds of plastic packaging products, labels, machinery and equipment protection, surface covering and many other things are produced from this film. This plastic protects the items inside it from oxygen and moisture and is used as a single-use packaging with a short shelf life. Polyethylene film in direct contact with the product guarantees a longer shelf life, helps to preserve its properties, prevents rapid drying and protects against environmental influences and contamination by external odors. If we want to examine the uses of polyethylene by industry, it will be categorized as follows:

- Packaging industry: The packaging of all consumer products, such as food and health needs requirements, all of which are met with this film. The flexible and waterproof structure makes the film the first choice of many industries to cover their products. On the other hand, due to its resistance and durability, it makes storage and shipping easy.

- Shipping industry: One of the main problems in shipping large loads is keeping the shipments organized and safe under harsh weather conditions. Polyethylene film provides everything needed for easy handling and hygienic storage.

- Agriculture and animal husbandry: This application is probably out of mind for many people, but it is one of the most critical applications of polyethylene film. For example, it is used for storing fodder, packing animal feed, and mulching the ground.

Types of Polyethylene Raw Material

Polyethylene is a type of polymer, and as mentioned in the previous sections, it is primarily used for packaging (plastic bags, plastic films and containers including bottles, etc.). According to Wikipedia, “As of 2017, more than 100 million tons of polyethylene resin are produced annually, which constitutes 34% of the total plastic market.” The types of polyethylene film are:

- Low-density or light polyethylene (LDPE): This material, abbreviated as LDPE, is used to produce plastic products such as shopping bags. LDPE is a very flexible material with unique properties.

- Linear Low-Density Polyethylene (LLDPE): This material is very similar to LDPE. The only difference is that it can be modified by adjusting the formula’s components to use less energy during production and produce better quality films with better properties. The products of Pushan Plastic Company are produced from this material, which offers a better structure than light polyethylene.

- High-Density Polyethylene (HDPE): This type of plastic has a denser form and is used to produce more robust products thanks to its highly crystalline structure. It is commonly used in making trash cans, milk and detergent bottles, cutting boards, and the like. HDPE plastic is also suitable for protecting groundwater from toxic chemicals from oil drilling or landfills.

Different Types of Multilayer Polyethylene Sheets

The classification of the last part was only based on the type of raw material, but another method of classification is based on the number of layers. Polyethylene film with one, three, five and seven layers and more is available in the market. The higher the number of layers, the higher the quality and strength of the final product. We will further examine this type.

- Single-layer polyethylene film: As the name suggests, this product consists of only one thin plastic layer. Its tear resistance is negligible and only suitable for covering surfaces. Of course, this model can be used for particular purposes, together with other products such as Aluminum.

- Two-layer polyethylene film: polyethylene sheets are easily placed on top of each other during production; as a result, it has a higher level of resistance, and the final plastic has a more significant quality and thickness. The two-layer film is suitable for the production of stretch film.

- Three-layer polyethylene film: the product produced by Pooshan Plastic Company is a three-layer type, and besides the appropriate thickness, it also has high elasticity and resistance. Compared to other products, the 3-layer model is the first choice of industries due to its more optimized features and better structure. This film is suitable for producing all kinds of plastic packaging in the food and pharmaceutical industries.

- Five-layer polyethylene film: In this type, five layers of polyethylene sheets are placed on top of each other, and as a result, the thickness of the film is high. The higher the number of layers, the lower the stretch and the higher the price.

- Seven-layer polyethylene film: You will see less of the 7-layer model in the industry, and as it turns out, it is thicker. But its elasticity is low, and the price is high.

- Laminated Polyethylene Nylon: Polyethylene film can be laminated with films such as Cpp, Bopp, and BoPet.

Features of White and Colored Polyethylene Film of Pooshan Plastic Company

This product is produced from the best polyethylene (LLDPE) materials and the latest equipment in Iran. This film is also known as nylon film, laminated film and printed film in the market, and it is the first choice of large industries for packaging their products.

The film has very high tensile strength and excellent resistance to tearing and abrasion; in addition, it is entirely anti-moisture and is the best choice for producing packaging for food and sanitary products such as pads and paper towels, etc. In fact, the product’s unique features make it possible to produce a wholly isolated and stable package with proper sealing to ensure the safety of the products sent. The product is also suitable for export goods.

In addition to using it raw, it can be used as a laminate with other films suitable for packaging, including Cpp, Bopp, BoPet and all kinds of metallized films, etc. Due to the high quality of raw materials, the transparency of this product is excellent, and it is the best choice for food packaging. Another feature of this film is its ability to be printed; therefore, various printing methods can be used according to the special needs of customers and users.

The film can be used as a single layer in advertising goods, food, and medicine packaging. This feature makes possible the production of handbags, milk bags, sanitary napkin packaging, diapers, cellulose products, etc.

Pooshan Plastic company’s packaging films have no difference in thickness, which means that it is also possible to stretch the film more in addition to having a pretty protective layer. As a result, your costs in this part will be significantly reduced.

Price List and Order Registration of Polyethylene Film

Pooshan Plastic produces all kinds of packaging films such as stretch film from polyethylene raw material. Milk and colored polyethylene film of Pooshan Plastic Company can be produced from 30 to 150 microns thick and 10 to 250 cm wide. The product delivery time will be on time and in the shortest possible time regardless of your order’s small or large tonnage. Settlement and payment conditions are adjusted according to customer requests (in cash and credit). Due to the use of the latest devices and the ability to produce in high tonnage, the prices are affordable, and the products are of good quality. To receive the proforma invoice and price list, contact the numbers listed on the site so that our sales experts can provide you with the necessary information. You can also use the order button on this page to send a request.

Remember that polyethylene film comes in a wide range of thicknesses, so the suitable model will vary depending on the product type and industry. Therefore, the greater the thickness of the final plastic, the greater the strength and the greater the weight-bearing capacity.

Reviews

There are no reviews yet.